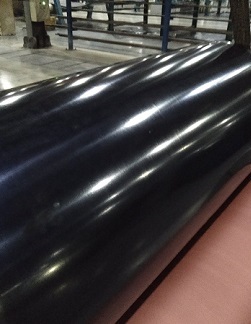

EP Conveyor Belt

EP Conveyor Belt

- Lower longitudinal elongation

- Full resistance to mildew, moisture and rotting

- Good flexibility and trough ability

- Short take-up lengths

- Product description: EP400/3; EP500/3;EP630/4

General Introduction:

EP rubber conveyor belt is widely used by the mining and processing industries for transporting bulk or lumpy materials such as quarrying, ore, coke, aggregates, crops, sand, clinker, chemicals, construction materials, etc.

The EP is short for Polyester fabric, which includes polyester toward longitudinal(warp) and polyamide for latitude(weft), EP fabric plies are sandwiched between rubber skim coats for adhesion and load support. Bottom and top cover compounds are added for maximum protection of the belt carcass. The EP conveyor belt consisting of two to six EP fabric plies, EP rubber conveyor belt has the same merit as Nylon conveyor belt, in addition, EP fabric has the advantages of:

A.Lower longitudinal elongation.

B.Full resistance to mildew, moisture and rotting.

C.Good flexibility and trough ability.

D.Short take-up lengths.

E.Suitable for middle and long-distance transportation of higher load and speed.

EP fabric also has excellent compatibility with other rubbers, so it can be combined with any type of cover grade to make it a perfect match for almost any application. This allows EP conveyor belt to convey basically any type of product in any environment, from fine powders to large lumps, from dry to greasy materials, from extremely cold to very hot conditions.

The common ep conveyor belt type could be:

2-ply belts: 315/2 400/2 500/2 630/2 800/2

3-ply belts: 500/3 630/3 800/3 1000/3 1250/3

4-ply belts: 630/4 800/4 1000/4 1250/4 1600/4

5-ply belts: 800/5 1000/5 1250/5 1600/5 2000/5

DIN22102 Standard:

| Standard | DIN-W | DIN-X | DIN-Y | DIN-Z | ||

| Tensile test | Before Aging | Tensile Strength (Mpa) | >18 | >25 | >20 | >15 |

| Elongation(%) | >400 | >450 | >400 | >350 | ||

| After Aging | Change rate of TS(%) | ±25 | ±25 | ±25 | ±25 | |

| Change rate of EL(%) | ±25 | ±25 | ±25 | ±25 | ||

| Abrasion test(mm³) | <90 | <120 | <150 | <250 | ||

AS-RMA Standard

| Standard | AS-N | AS-M | AS-A | RMA-1 | RMA-2 | ||

| Tensile test | Before Aging | Tensile Strength (Mpa) | >17 | >24 | >17 | >25 | >18 |

| Elongation(%) | >400 | >450 | >400 | >450 | >400 | ||

| After Aging | Change rate of TS(%) | ±20 | ±20 | ±20 | ±25 | ±25 | |

| Change rate of EL(%) | ±20 | ±20 | ±20 | ±25 | ±25 | ||

| Abrasion test(mm³) | <200 | <125 | <70 | <125 | <200 | ||

Muti-ply EP Fabric Grade (Tensile Strength kg/cm, PIW):

| Fabric/Ply | 3P | 4P | 5P | 6P | ||||

| kg/cm | PIW | kg/cm | PIW | kg/cm | PIW | kg/cm | PIW | |

| EP-100 | 300 | 1680 | 400 | 2240 | 500 | 2800 | 600 | 3360 |

| EP-125 | 375 | 2100 | 500 | 2800 | 625 | 3500 | 750 | 4200 |

| EP-150 | 450 | 2520 | 600 | 3360 | 750 | 4200 | 900 | 5040 |

| EP-200 | 600 | 3360 | 800 | 4480 | 1000 | 5600 | 1200 | 6720 |

| EP-250 | 750 | 4200 | 1000 | 5600 | 1250 | 7000 | 1500 | 8400 |

| EP-300 | 900 | 5040 | 1200 | 6720 | 1500 | 8400 | 1800 | 10080 |

| EP-350 | 1050 | 5880 | 1400 | 7840 | 1750 | 9800 | 2100 | 11760 |

CATEGORIES

LATEST NEWS

- Which Country is The Best Choice for Purchasing Conveyor Bel2021-11-11

- What are the most commonly used areas of belt conveyors?2021-06-24

- Analyze the importance of flame-resistant conveyor belt from2021-06-10

- The most important index of rubber conveyor belt-----Tensile2021-06-09

- Carbon Black----One of the key factors affecting the quality2021-05-27

CONTACT US

Contact: Overseas Department

Phone:

Tel: +86-312-5308005

Email: info@sungdagroup.com

Add: Boye Rubber Industry Technical Development Park Baoding city, China